Our Services

Our key services with demonstrated capabilities include:

Valves and Wellheads

Knotswap Services is your go-to oilfield wellhead resource. We can accommodate any wellhead through our wellhead equipment sales, rentals, or maintenance services. Take the stress out of starting up an oilfield wellhead or expanding your business to new sites. We can keep your equipment up to code, well maintained, and provide any necessary repairs — either on site or in our in-house facility.

We keep a large supply of wellhead equipment on hand for rental and sale. This includes but is not limited to:

- Casing hangers

- Tubing hangers

- Tubing heads

- Tubing spools

- Tubing head adapters

- Flow tees

- Tree assemblies and caps

- Chokes (both positive and adjustable)

- Ball valves

- Gate valves

- Plug valves

- Pressure testing

- Plug valves

- Pressure testing

- Well maintenance

- Mobile accumulators

- Heaters

- Hot shot

Drilling solids control management.

Knotswap provides a full range of equipment and solutions intended for high performance and reliability. Addressing optimization of solids control and waste management systems provides our customers with economic and effective solutions for the most challenging drilling environments. Our technologies, services, and highly-trained field technicians are developed to ensure our customers achieve compliance amid evolving environmental regulations and diverse waste materials encountered.

Our advance planning, holistic approach and novel technology leads, but not limited to:

- Increased drilling effectiveness and efficiency.

- Maximum cost savings via maximum solid removals.

- Optimal efficiency by maintaining drilling fluids properties.

Water based mud treatment

We provide and use high quality water and waste water treatment chemicals, specialty chemicals, tracer dyes, water test kits, reagents, testing, analysis, dosage and control equipment.

Knotswap provides consistent results with clients due to environmental complaint processes we follow, at the same time achieving increased particle and oil recovery from producing wells. We work with our clients to lower costs, reduce HSE and economic risks, and optimize drilling efficiency.

Our WBM treatment services include:

- Liquid phase treatment.

- Solid phase treatment (Drill Cuttings).

- We recycle the secondary wastes (i.e., treated solid and liquid wastes).

- However, our disposal option is in accordance with that

approved by department of petroleum resources (DPR) and other regulatory agencies.

Our technology provides our clients with:

- Water- clarified water can be recycled for re-use e.g., rid cleaning

- Pit volume- reduced or in some cases eliminated as water is reclaimed and reused.

- Environmental impact- greatly reduced due to a combination of less water being required to drill the well and less discharge.

- Chemical consumption- minimized due to efficient real time mixing and dosing

- Mixing- efficient mixing powered, granular or micro-bead coagulant/flocculent reduces the cost of using expensive pre-mixed solutions.

Environment Studies

Knotswap offers the following amongst others:

- Environmental Impact Assessment (EIA)

- Consultancy

- Risk Assessment

- Environment auditing

- Baseline studies

- Compliances

- Safety cases

Equipment leasing and logistics

Knotswap provides brokerage and transportation support services

to industries, delivering higher levels of service, greater reliability and more control over your product movement. Our expert management and staff offer a unique blend of talent and skill to our clients. We maintain the highest degree of professionalism and promptness.

Our goal is to safely transport your equipment and goods to stipulated destination at the right time in good condition. We know every business has different needs. That’s why Knotswap will help transform your transportation needs into transportation solutions. We render holistic studies and deliver accurate and detailed reports in all our environment studies, on time and within budget.

Waste management

Knotswap’s division remains a cornerstone of the company’s operations. Currently, we are involved in both municipal and private contracts where we manage waste from households, schools, and businesses, maintaining a high level of service delivery throughout the country. Our operations include on-site waste management, recycling initiatives, as well as the removal of rubble and construction waste.

Hazardous waste handling

The cuttings generated during the oil based md sections are quite hazardous and require a specialized method treatment. These cuttings are usually highly contaminated with oil based mud. For effective treatment, they have to be transported to the location of the thermal desorption unit in a manner that is not harmful to man and the environment. Knotswap technical services limited provides spill proof skips that are all certified to international oil and gas industry standards and are designed in such a way to prevent accidental spillages in areas that the hazardous waste may cause serious damage to both man and his environment.

In addition to this, Knotswap has in place an excellent logistics team in place that

ensures that the transportation of the waste from where it is generated to the treatment site ensuring that there is no negative environmental impact. Our vehicles are also highly maintained and pre-mob vehicles that match the current industry standard. The drivers are also highly trained on the safe methods of transporting hazardous waste as well as defensive driving.

The waste management expert constantly communicates with the

logistics team to ensure a smooth execution of the projects

Filtration Services

Knotswap Technical Services Limited has a state of the art filtration system that is uniquely designed for effective particle removal that ensures the fluid purity is optimized which is critical to maximum production. The Knotswap ideology in handling projects is that every project is unique. This is why our highly trained field specialists design the best practicable system to handle the filtration requirements of all our esteemed clients.

We offer the following brine filtration services;

- Filtration and separation

- Completion fluids

- Work over chemicals

- Pre-completions wellbore clean up tools

- As a rental/service company, we can supply all components and personnel required to carry out filtration operations.

Our filtration system provides many benefits which include:

- Improved recovery of completion fluids and brines

- Preventing blockage of formation pore and perforations

- Prevention of solid accumulation in the well annulus

- Safeguarding the completion assembly from particle settlement

- Meeting the discharge compliance legislations of the regulatory agencies

- Optimizing well performance

Produced water treatment

KIn addition to filtration services, Knotswap specializes in water treatment processes and technologies to remove all oil, hydrocarbons, heavy metals, solids, toxic materials and other contaminants from your operations waste water stream. Knotswap provides consistent results to produce environmentally compliant processes with increased oil recovery and production.

How our Produced Water Treatment systems work:

- Conventional pre-treatment, such as corrugated plate separation, hydrocyclones, air flotation or sand filtration is used to remove the bulk of the oil and suspended solids.

- The ‘clarified’ water is physically polished by membrane Ultrafiltration, which reduces oil concentration to less than 0.3 mg/l, and suspended solids to below the limits of detection. The Ultrafiltration membranes utilize a modified polyacrylonitrile chemistry, which has been developed to be extremely oleo phobic and thus resistant to free-oil fouling.

- The oil and suspended solid free water is treated using membrane Nanofiltration, which removes the bulk of heavy metals and organic compounds. Nanofiltration provides negligible resistance to the passage of monovalent ions such as chlorides, so it is able to operate on high salinity waters where the inefficient productivity of Reverse Osmosis would render it uneconomical.

Tank Cleaning

We provide extremely cost-effective tank cleaning services, using the most advanced tank cleaning technologies available to ensure that tanks are taken out of use for the minimum time.

With highly trained operatives, our cleaning methods for both manual and automated fuel tank cleaning meet and frequently exceed the latest compliance and health & safety standards. We use powerful remote-controlled mechanical washers to speed up tank cleaning, reducing downtime and man-entry costs such as scaffolding.

For manual tank cleaning, our operatives are trained to operate in confined spaces using breathing apparatus and jetting equipment. Where necessary, we use cold cutting techniques to access enclosed tanks, and will uplift and transfer fuel and residues. We follow up cleaning by testing and issuing gas-free certification.

We also offer other storage tank cleaning services which include but not limited to:

- Fuel tank cleaning

- Oil tank cleaning

- Diesel tank cleaning

- Underground tank cleaning

- Water tank removal

Onshore/offsite cutting treatments

Constituents from a waste stream in such a manner that they are preserved for collection and recycling. It involves the use of thermal energy to remove the volatile oil from the cuttings in a manner that both constituents are still suitable

for reuse and recycling.

After successful transportation of the contaminated cuttings from the drilling site to the treatment site, the cuttings are tested to determine the chemical characteristics of the cutting contaminated with oil. This will determine the treatment method to be employed and will also be useful in determining the effectiveness of the treatment method. The waste to be treated is properly screened and undergoes several processes and stages to separate the oil from the cuttings. The temperature used to achieve the separation is just enough to ensure that the nature and characteristics of the oil based mud is not destroyed.

Completion services, hoisting and supply of drilling rigs.

With our thorough understanding of the terrain and nature of drillings sites in Nigeria, Knotswap can certainly offer rigs of various draws works, rated drilling depth, industry standard top drive and md pumps to ensure that your drilling program in Nigeria is optimized.

Some of the factors we take into consideration include;

- Mud pumps

- Draw works

- Rotary with New Power

- Controlled mud systems

- Rog control equipment

- Modular AC and DC Draw works

- Rack and pinion rigs-push/pull rigs

- Rig automation equipment

Knotswap Technical Services Limited has highly experienced completion team combined with a portfolio of modern technologies and a thorough understanding of the Nigeria Domain ensures that the project specific solutions we provide help our clients optimize recovery and reservoir drainage.

Our completion services include but not limited to:

- Sand control/gravel packing services

- Integrated completion fluids and tools

- Casing and tubing

- Cementing

- Perforation

- Safety and isolation valves

- Down-hole completion equipment

- Linear hanger systems

The benefits of using our completion service include;

- A clean producing zone

- Minimal formation damage

- Lower NPT

- Longer well productive life

- Reduced cost

- Minimal environmental footprint

Slickline

Today, to cut well intervention costs and boost production, we collaborate closely with you in every part of the world. It’s not surprising that everything starts with experienced, well-trained Knotswap professionals who help cut the frequency of trips into the well and restore full production with

minimum NPT and innovative solutions.

Count on us to provide every slickline capability from basic completion intervention applications to advanced services, from recording accurate flow profiles or reservoir boundaries to perforating, setting packers, and other mechanical interventions typically performed on electric line. Here’s where you’ll find slickline technologies brought to the peak of performance – as only our team members can.

Our slickline tools include but are not limited to; jar, stem, pulling tools, lead impression blocks e.t.c.

Typical lists of services we offer under slickline include but are not limited to:

- Total depth tagging

- Gauge ring runs

- Broach tubing/ plunger installation

- Bailing sand and debris

- Shifting sleeves

- Setting/pulling plugs and chokes

- Setting/pulling gas lift valves

- Running tailpipes

- Bottom hole pressure and temperature surveys

- Spinner surveys

- Sand cutting and caliper

- Memory production logging

- Fishing operation, e.t.c.

Sand Trap

Our Sand Trap services include pumping, transporting, and disposal of grease traps, sand traps, truck washes, equipment washers, and industrial non-hazardous liquid waste. Our truck and pump operators have the experience needed. We do our best to bring you dependable and efficient service in cleaning traps and drains. We have the right equipment to service your needs whether the job is easy access or hard to reach. Pressure washer/jetter machines are available to clean drain lines as well.

Other services include:

- Pumping and transportation

- Grease trap pumping

- Sand trap cleaning

- Liquid industrial non-hazardous waste

- Trap maintenance.

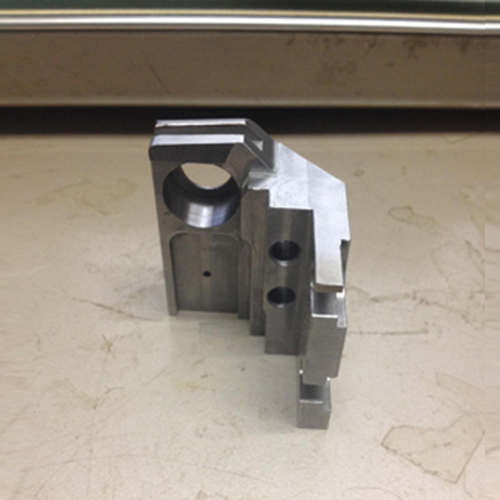

Machining

For excellent precision machining of your industrial tools, trust only a professional machine company to get the job done right the first time. Turn to Knotswap Energy and Technical Services Limited. We are the company of choice when it comes to fast, reliable, and high quality precision machining services. Whether your business requires grinding or heat treatment, we will take care of your needs.

We understand that our work is essential to your daily business operations. That’s why we make sure that our team is comprised of only of trained, experienced, and innovative machinists who go above and beyond their respective duties in providing our customers with high quality services. Rest assured that with us, your tools are in perfect shape.

OCTG Tubing & Casing Supply

We are a supplier and factory of OCTG Tubing and OCTG Casing in Nigeria. We have our own facilities of OCTG tubing and Casing and all precision rolling pipes.

Our experienced OCTG specialists will formulate a comprehensive and customized approach that will meet customer needs for projects worldwide. We supply Tubing, Casing and Premium Connections in seamless, welded, duplex, chrome, alloy and carbon. Our product line also includes insulated conductors, sucker rods, and drill pipe in both standard and heavy weights. Additionally, Knotswap’s value added services and focus on our customers needs will ensure a better return on investment. These tubular products have broad application in oil and gas.

We deliver on time and always give quality and can work cost efficient.